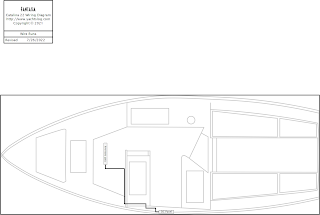

Five years ago, we created the control panel for our Catalina 22, Fantasia. We needed to add another control to the panel for the bilge pump and re-do much of how the wires are run, so are taking this opportunity to show how we put it together. This is mounted on the shelf above the table of the 1985 and before Catalina 22s. (This scheme won't work on later Catalina 22s that don't have a shelf.)

|

| Panel before bilge pump switch added. Ignore the hanging wires which were still being worked on when this shot was taken. |

DO NOT DO ELECTRICAL WIRING IF YOU DON'T KNOW WHAT YOU ARE DOING. YOU CAN CAUSE SERIOUS, POSSIBLY FATAL, DAMAGE TO YOU OR YOUR BOAT, OR POSSIBLY BURN DOWN THE ENTIRE MARINA BECAUSE OF YOUR MISTAKES.

Note that I am not a professional boat installer. You are entirely responsible for determining if this is safe. I am merely describing what I did, not telling you to do the same. If you do manage to burn down your marina, you are entirely responsible, not me!

|

| Foam board template |

We started by creating a template out of foam board. Note that the panel is not rectangular, but is instead a trapezoid higher on the right side, about 8" on the left and 9" on the right. We acquired a 1/4"x10"x4' teak board, of which about two linear feet are used here for the front panel and the rest for side panels. A friend with a complete woodworking shop cut the board for us and holes for us, but we used a Dremel tool and a Dremel Shaper & Router Table 231 for the bilge pump switch and constructing our AC panel. The finished edges didn't look quite as good, but the holes are concealed by the edges of the various controls, so it didn't matter.

|

| Panel after addition of bilge pump cutout. |

Stuff on a boat is dictated by two sets of standards bodies and their publications: US Coast Guard 33 CFR Part 183 - Boats and Associated Equipment, and American Boat and Yachts Council (ABYC). The specific standards that relate to electrical systems are 33 CFR Subpart I - Electrical Systems and E-11 AC & DC Electrical Systems on Boats. Unfortunately, the E-11 standard is not public, and the price will cause some sticker shock (currently $195). For that reason, I work off the 2008 version which I managed to lay my hands on and assume that not that much changed since then.

The panel itself:

- Teak board 1/4"x10"x4' @ $15.95 a linear foot.

- Oak 1"x2"x4' board for U frame.

The various components that are installed in the panel are:

- Standard Horizon Eclipse DSC GX1000S White VHF (came with the boat, but a similar one can be bought for around $155), held in place with a Standard Horizon Flush Mount Kit STD-MMB-84 ($13.91).

- Blue Sea Systems M-Series Mini Selector - 6007200 ($33.07)

- Sea-Dog Line Battery Test Rocker Switch LED 425020-1 ($40.95)

- West Marine Electrical Panel DC 6 Circuit 8932 ($54.99)

- West Marine Electrical Panel DC 4 Circuit + 2 12v Power Outlets 8931 ($64.99)

- Sea-Dog Line USB Power Socket 426502-1 ($18.74)

- Blue Sea System Bilge Pump Switch 8263 Contura ($39.88)

For the back panel, we needed:

- Sea-Dog Line Bus Bar Screw Terminal 10x #8 426711-1 ($9.97)

- Two of Blue Sea Systems Fuse Block 5037 ($27.89 each)

- 16 AWG marine wire in various colors

- 10 AWG marine wire to go to the batteries

- Split Loom

- Wiring Connectors

- Stainless steel screws

- Brass bolts, nuts, hinges, and screws

At the batteries:

- Two Interstate 24M-AGM-A batteries ($219.95 each)

- Two Blue Sea System Battery Terminal Mount Fuse Block 5023 ($19.12 each)

- Blue Sea Systems m-ACR automatic charging relay 7601 ($70.77)

The West Marine four switch panel has outlets for two 12V outlets. I removed and replaced one of the two outlets with the Sea-Dog USB ports. This has an incorporated 12V to 5V step-down transformer and is an easy swap. This allows charging cell-phones and such while at sea. As a note, the West Marine panels are OEMed by Blue Sea Systems, which now sells similar models in grey instead of black and already have the USB ports.

The panel mounted on a frame made of the oak board formed in the shape of a

U. These were glued together with wood glue and pocket screws and sized

exactly to the opening. This frame was routed out with a Dremel tool at

various points to make room for screw heads and some of the controls. This

was screwed into the shelf teak panel with stainless steel screws. Holes

were drilled from the back side and brass bolts were inserted. This holds

the top of the teak panel and held in place with knurled nuts. The bottom

has brass hinges, also held in place with brass bolts and knurled nuts. This

makes access to the back of the panel very nice, as the top knurled nuts are

removed and the entire panel hinges down. On the back of the shelf, some

thin backing board was fixed to which the connector blocks, fuse blocks, and

negative bus bar are all affixed with stainless steel screws.

Holes were drilled and routed with a Dremel tool into the bottom of the shelf. This allowed all wires to be hidden from view in the cabin by routing them beneath the shelf. These holes were protected with cable glands, although on some later holes we 3D printed rubber bushings to keep wires from getting cut on the edges.

| DC Wiring Diagram. This is a system wiring diagram that shows both physical layout and electrical connections. Components below the horizontal dashed line are on the front panel. Components in the upper right are on the back panel. Components in the upper left and in rectangular boxes are elsewhere on the boat. |

Following the ABYC standard, DC negative wires on a boat should be yellow or black (TABLE XIII - WIRING COLOR CODE). However yellow is preferable for DC negative to differentiate them from the hot wires in an AC system which are black. Some DC components (such as the VHF radio) came with black negative wires. For those, I wrap the ends of the black wire in yellow electrical tape to make it clear that they are DC negative wires and not AC hot wires.

The ABYC standard says that a fuse or breaker must be within 7" of the battery (E-11, 11.10.1.1.1) unless the wires are in a conduit. The Blue Sea Systems Fuse Block 5037 mounts directly on the battery terminal and provides that fuse. I figure more fuses are better, so this layout has some that are redundant. For example the West Marine panels have a 15 amp circuit breakers built in, but I still have a smaller fuse behind it. I have all LED lights on the boat, so there should not be much current draw at all, so if any fuse blows it probably means something really bad happened, by which I mean a short circuit.

|

| Wiring for the bilge pump |

|

| Wiring for the AC panel |

|

| Wiring for VHF |

|

| Wiring to mast |

|

| Wiring to VHF Antenna |

|

| Wiring to cabin lights |

|

| Wiring to fan |

|

| Wiring to chart plotter |

|

| Wiring to cabin lights |